About this Product

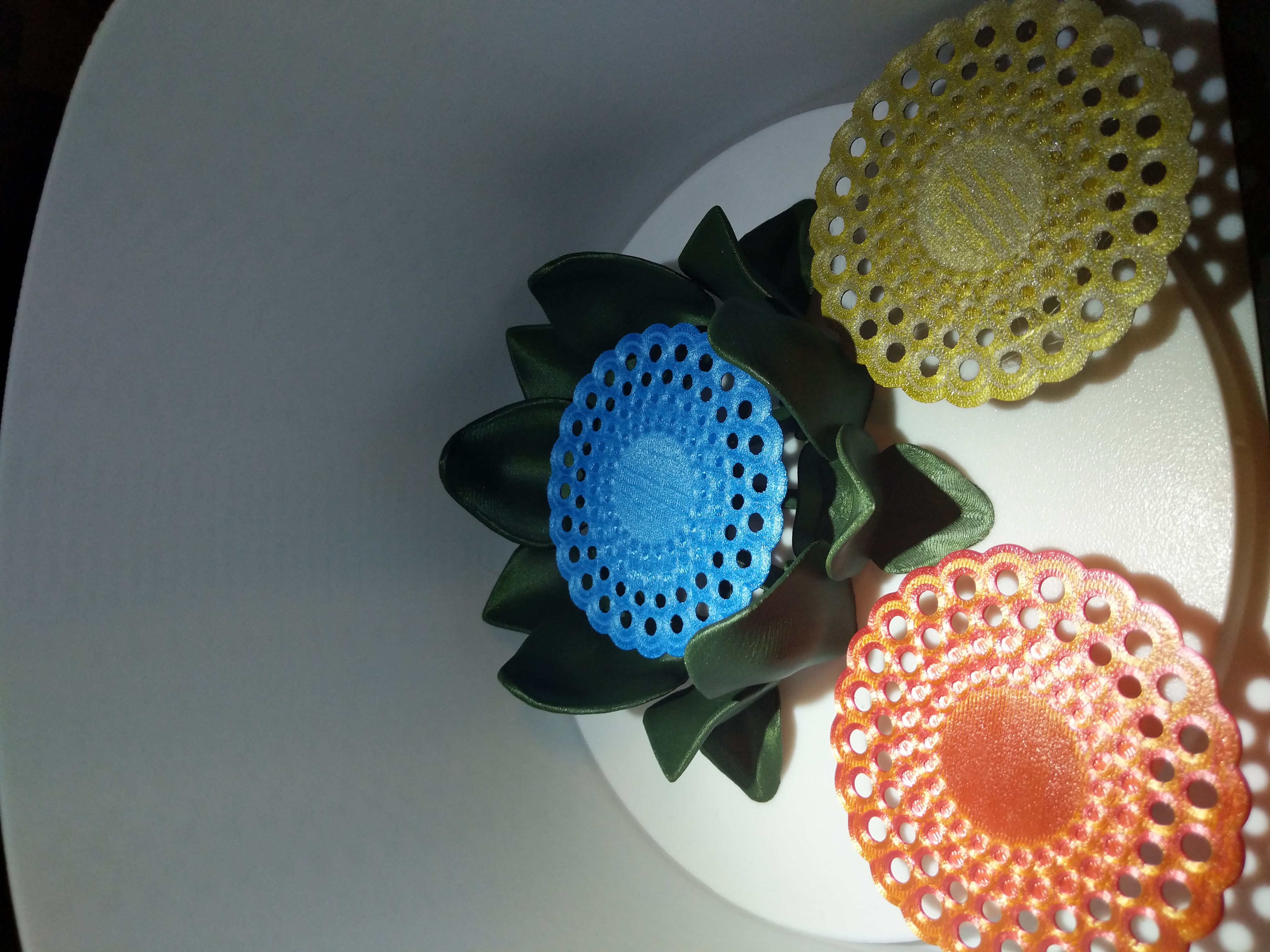

Add a touch of elegance and functionality to your space with this 3D Printed Flower Self-Adjusting Coaster! Designed with a flexible petal mechanism, this coaster adapts to different cup sizes, ensuring a stable and secure hold for your drinks. Whether you choose Marigold (vibrant orange), Buttercup (soft yellow), or Morning Glory (serene blue/purple), each design is crafted with high-quality PLA plastic, making it both lightweight and durable.

Perfect for home, office, or as a unique gift, this stylish coaster not only protects your surfaces from condensation and heat but also brings a floral charm to your décor! ?✨

? Features:

✔ Self-Adjusting Petals – Flexes to fit different cup sizes, ensuring stability ✔ Eco-Friendly PLA Material – Made from biodegradable, plant-based plastic ✔ Available in Three Gorgeous Floral Designs – Marigold, Buttercup, and Morning Glory ✔ Durable & Lightweight – Ideal for everyday use at home or work ✔ Unique & Handmade Feel – 3D printed for a modern, artistic touch

? Why You’ll Love It:

✅ Aesthetic & Functional – Combines beauty and practicality in one design ✅ Perfect for Gifting – Great for coffee lovers, tea enthusiasts, or plant lovers ✅ No More Spills – Keeps your cup secure with an adaptive design ✅ Eco-Conscious Choice – Sustainable alternative to traditional plastic coasters

?️ FAQs:

❓ What is PLA plastic? ✔ PLA (Polylactic Acid) is a biodegradable plastic derived from renewable resources like corn starch, making it eco-friendly and safe for everyday use.

❓ Can I use this coaster for hot drinks? ✔ Yes! PLA is heat-resistant up to a certain temperature, but it's best to avoid placing extremely hot items directly on it.

❓ How do I clean it? ✔ Simply wipe it with a damp cloth. Do not put it in the dishwasher, as high temperatures may warp the material.

❓ Can I request a custom color? ✔ At this time, the coaster is available in Marigold, Buttercup, and Morning Glory, but feel free to reach out for special requests!

DehneCraft 3D Workshop

Meet the Maker

A 41-year-old Minnesotan with a passion for video games and a growing interest in 3D printing. Always up for a new challenge, I'm excited to explore the creative possibilities of additive manufacturing and combine it with my love for gaming. When I'm not designing and printing, you can find me immersed in a virtual world or exploring the beautiful landscapes of Minnesota.

How it’s Made

How 3D Printed Items Are Made: A Step-by-Step Guide

3D printing is a revolutionary technology that turns digital designs into physical objects layer by layer. It’s widely used for creating everything from prototypes to intricate figurines, custom tools, and even medical implants. Here’s how the process works:

?️ Step 1: Designing the 3D Model

Before anything can be printed, a digital blueprint of the object is created using 3D modeling software like Blender, Tinkercad, or Fusion 360. This file is usually saved in an STL or OBJ format, which defines the shape and structure of the object.

? Step 2: Slicing the Model

The 3D model is then processed using a slicing software like Cura or PrusaSlicer. This software slices the digital model into thin horizontal layers and generates a G-code file, which tells the 3D printer exactly how to print the object.

?️ Step 3: Printing the Object

The 3D printer follows the G-code instructions and starts building the object layer by layer using one of several printing technologies:

FDM (Fused Deposition Modeling): The most common method, which melts and extrudes plastic filament (like PLA or ABS) through a heated nozzle.

SLA (Stereolithography): Uses a laser to cure liquid resin into solid layers for high-detail prints.

SLS (Selective Laser Sintering): Uses a laser to fuse powdered material into solid shapes.

For FDM printing, the printer moves its nozzle along the X, Y, and Z axes, depositing melted filament that cools and solidifies to form the object.

⏳ Step 4: Cooling and Post-Processing

Once printing is complete, the object cools and solidifies before it’s removed from the print bed. Some prints require additional post-processing, such as:

✅ Support Removal – If the print has overhangs, temporary supports may need to be removed. ✅ Sanding & Smoothing – For a polished look, prints can be sanded or treated with solvents like acetone. ✅ Painting & Finishing – Many prints can be customized with paint, resin coating, or dyes.

? Why 3D Printing is Popular:

✔️ Customizable – Create one-of-a-kind designs with ease. ✔️ Eco-Friendly – Many filaments, like PLA, are biodegradable. ✔️ Fast Prototyping – Great for inventors and small businesses. ✔️ Cost-Effective – Print complex objects without expensive molds.

Whether you're printing a flexible axolotl, jewelry, or engineering parts, 3D printing makes it possible to bring digital creations to life! ?

Let me know if you need more details! ?

_1724610772986_png_794404163944_1724610772.png?t=1724611178)