About this Product

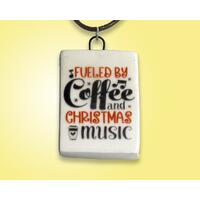

Discover the perfect Christmas accessory with Snowman with plant Ceramic Post Earrings.

All our ceramic pieces are handmade in America, near the Great Smoky Mountains National Park.

- Waterproof can be worn in the shower or in the pool

- Made from earthenware clay

- Fired in a kiln

- Earrings are approximately .625 x .625 inch

AMayesPotteryandJewelry

Meet the Maker

A Mayes Pottery and Jewelry is part of PGF Designs, a graphic design company located in Sevierville, TN near the Great Smoky Mountains National Park.

Pamela Fisher Mayes is the owner/designer and operator of A Mayes Pottery and Jewelry. Pam is a graphic designer, designing print material and web designs for local businesses. Always eager to learn new things she decided to try her hand at pottery and fell in love with the art of handbuild pottery. Once she learned the basics, she started seeing the possibilities of tying her tech and design skills to her ceramics.

A Mayes Pottery features 3D printed clay stamps for other potters to use as well as some finished ceramic pieces. A Mayes Jewelry features a unique collection of handcrafted, kiln fired ceramic jewelry for a variety of tastes, occasions and events. This GoImagine shop features the best from both brands in one location.

How it’s Made

All our jewelry starts out as a 25 pound block of clay. After removing a pound or two we place that in our slab roller. From there we use cutters and stamps most of which were printed on our in-house 3D printers, to cut the clay into the different jewelry and product pieces you see.

Once the shapes are cut they are place between layers of wood and left to dry from a couple of days to a week or more depending on the design and the humidity in the weather.

After being dried we use a wet clay sponge to clean up the edges and smooth rough spots. Once the pieces have dried again, it is placed in one of our kilns to be bisque fired. Bisque firing takes over 24 hours from the time the pieces are placed in the kiln, allowed a couple of hours to reheat at a low temp and then slow fired to over 1800°

After being bisque fired many of the terracotta pieces are ready to be finished as jewelry and packaged making them ready for their new home.

The colorful pieces and the ones with designs on them are not final after the being bisqued. They need to be glazed and run through another kiln firing again reaching from 1800° to 2200° and taking another day to complete this process.

The jewelry designs and other pieces which have colorful art or wording on them have to go through even another firing to permanently infuse the art into the piece. This means another day in the production process.

All of this to say... Making handmade, kiln fired, ceramic jewelry is not a fast process but it is a process done in tradition and care for our customers.

To learn more about our process and see ahow some of our products are made visit our youtube channel https://www.youtube.com/@amayespottery