About this Product

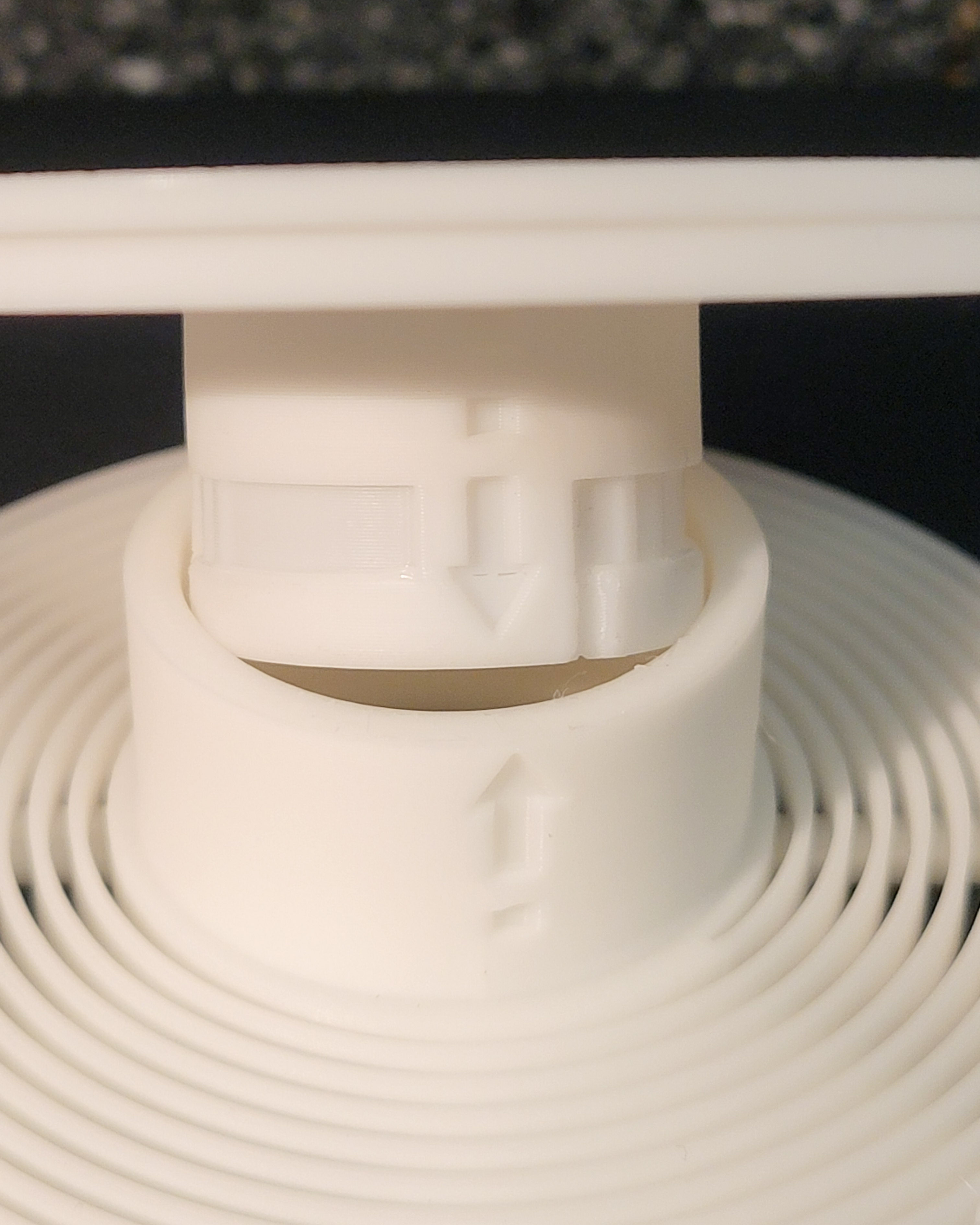

My Pa-APS reels let you develop APS (Advanced Photo System) format film in a Paterson processing tank.

My completely new reel design lets you develop APS (Advanced Photo System) format film in a Paterson processing tank easier than ever!

They are 3D printed, and have been redesigned and refined through a lot of user feedback. They are printed in PLA+ material, which has proven to be sturdy and resilient when used with any typical (and some not-so-typical) development process, including B&W, C-41, E-6, ECN-II, etc.

They have a built in twist-lock system, that separates into two halves for easy film unloading after development is finished

Your order can can also include an optional set of APS canister tools, which I designed to help with opening the APS film gate, and extracting the film. The APS Canister tools are an optional add-on, so if you want them be sure to select the "w/APS Can Tools" option when ordering. I've made a video that shows using the APS Canister Winder tool, so you can see it in action. You can watch the video here:

Here are a few of the highlights of the new design:

Added “twist-load” ability, while retaining my (still) preferred “push-fed” lock-in-place design

2) Increased film strip capacity by 44%. This new design now supports lengths of up to (approx) 190cm (74 3⁄4”). 40 EXPOSURE ROLLS ARE NO LONGER AN OBSTACLE!

3) Improved anti-crawlback design, to better lock the film strip in the reel during development

4) New design allows for improved chemical/liquid flow

5) New “lock/unlock” icons on the reel’s face that are easier to see and understand

6) New Paterson center rod/core interface design, for better overall compatibility with decades of Paterson manufacturing variances

7) Improved reel crossbar design for an even smoother loading experience

8) Improved overall reel left/right half interfaces, for steadier and smoother reel separation and reconnection

Things to consider when ordering:

Do you need to also get a set of the (optional) APS canister tools to help with opening the canister's film gate, and retrieving the film?

APS 40-frame film rolls are now supported with this new redesign!!!

These reels are printed on-demand, which typically takes a few days (occasionally longer, but not often). I send notice when your order has finish printing and has been hand-tuned, and checked for quality and usability, so you know how things are progressing.

Tips for best use of these reels:

Before using them, get familiar with the functionality of your new reel(s) and APS Canister Tools (when applicable). Take time to separate and re-join the two halves. Notice the alignment arrows, and pay attention to locking direction and feel. Do it all without film first.

Film Stuff Lab

Meet the Maker

I have a strong passion for photography in general, and film/analog photography specifically. I also tend to lean into the more unique film formats, which definitely added challenges to home developing (amongst other things), so I started making my own solutions. Other people saw some of my creative (and money-conscious) solutions and started asking me if I could help them out too, which is why I opened up a shop so that sharing my creations could be easier to do, and so I would be and able to reach more people who were having the same problems I had faced.

I have two main goals with this shop. First is to offer easily usable and affordable solutions to film developing problems that I encountered. Most notably, development reels for formats that aren't readily available. My second goal is to offer affordability. Like for real, not as a sales pitch. I am 100% sure that my offerings fall into at least one of two categories; (1) Unique and usable. Many of my offerings are only available through my efforts, and not anywhere else. (2) Best value for price. A couple of the things I offer might have alternative options out in the world, but those are all so wildly overpriced than I decided to make an affordable one, first for me, then for anyone else who might be interested.

Everything I offer has been created by me, out of my personal need for a high quality, and also affordable, solution. Rest assured that if I am offering it here, it is because I am myself using it and have gotten it to a point of satisfaction in quality and usability that I feel it would benefit others as well.

How it’s Made

My reels are 3D printed, and have been designed and refined through a lot of user feedback. They are printed in PLA+ material, which has proven to be sturdy and resilient when used with any typical (and some not-so-typical) development process, including B&W, C-41, E-6, ECN-I1, Cafenol, etc.

Shop Policies

Buyer can contact seller about any issues with an order.