About this Product

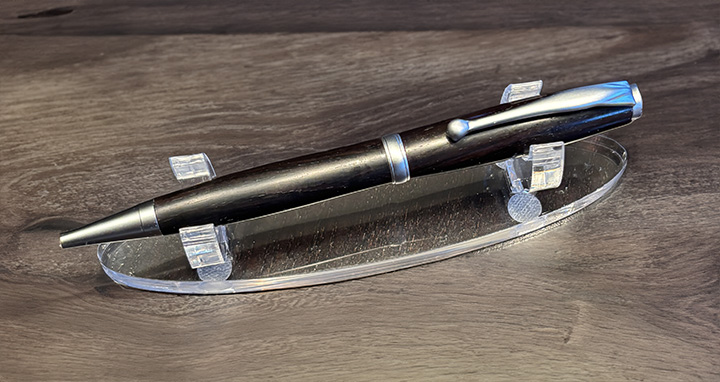

Hand-Turned African Blackwood Pen

Experience the elegance of fine craftsmanship with this hand-turned African Blackwood pen. Renowned for its deep, lustrous tones and smooth, polished finish, African Blackwood is one of the most sought-after materials in the world of woodworking. This pen is a testament to the timeless beauty and durability of this exceptional hardwood.

Carefully crafted by hand, the pen features a sleek, ergonomic design that feels balanced and comfortable in your hand. The natural dark hues and subtle grain patterns of African Blackwood exude sophistication, making this writing instrument perfect for professional settings, journaling, or as a cherished gift.

Fitted with premium hardware and a smooth ink flow mechanism, this pen is as functional as it is beautiful. Whether signing important documents or writing personal notes, it transforms every task into a luxurious experience.

Handcrafted with precision in Austin, TX, this African Blackwood pen celebrates the union of artisanal skill and the world’s finest natural materials. A perfect choice for collectors, professionals, or anyone who appreciates the art of fine writing instruments.

Turncoat Studios ATX, LLC

Meet the Maker

Everything we do starts with the wood. We search out both highly figured and simple, even grained woods. The selections are based on both appearance and functionality.

The turning process starts with an idea of the finished piece and the wood dictates the rest. When we are ready to start, it’s mask on, wood spinning, and we apply tools to the wood. The process results in a compromise between what we want and what the wood will allow. Never fight the wood. All of these pieces are turned on our lathe, in our workshop, by our hands.

With the piece turned and sanded it is time for paint. We take inspiration from nature, cultures, artistic movements, and the shape of the piece and the complexity of the grain. The designs run the gamut from simple to complex and from large to small as the piece suggests. Sometimes the designs take days, returning to the piece multiple times to add touches. We hope these pieces give you years of service and beauty.

How it’s Made

Creating a hand-turned wood pen is a meticulous and rewarding process that transforms raw wood into a functional work of art.

1. Selecting the Material

The process begins with choosing the wood or composite material. Popular choices include exotic hardwoods, burls, or engineered materials like SpectraPly. Each blank is selected for its unique color, grain pattern, and character.

2. Preparing the Blank

The wood blank is cut to the appropriate size for the pen kit being used. The blank is then drilled through the center to accommodate the pen’s brass tube, ensuring precise alignment.

3. Gluing the Tube

The brass tube, which forms the core of the pen, is glued into the drilled hole using epoxy or CA glue. This provides a secure foundation for the pen components. After the glue cures, the ends of the blank are trimmed or squared to ensure they are flush with the tube.

4. Mounting on the Lathe

The prepared blank is mounted on a mandrel, which holds it securely on the lathe. Bushings corresponding to the pen kit are placed on either side of the blank to guide the shaping process.

5. Turning the Blank

Using specialized turning tools, the woodworker shapes the blank while the lathe spins. The goal is to create a smooth, contoured profile that transitions seamlessly to the bushings. This is where the artisan’s creativity shines, allowing for unique designs and finishes.

6. Sanding

Once the desired shape is achieved, the pen blank is sanded progressively with finer grits of sandpaper. This removes tool marks and prepares the surface for finishing. Care is taken to ensure a silky-smooth texture.

7. Applying the Finish

A finish is applied to protect the wood and enhance its natural beauty. Popular finishes include friction polish, CA glue, or polyurethane. Each method creates a durable, glossy, and professional-looking surface.

8. Assembly

After the finish cures, the blank is removed from the lathe. The finished components are assembled using the pen kit hardware, which typically includes the pen mechanism, nib, clip, and cap. Assembly is done carefully to ensure all parts fit snugly and align perfectly.

9. Final Inspection

The completed pen is inspected for quality, ensuring it writes smoothly, feels comfortable in the hand, and showcases the craftsmanship and material’s beauty.

10. Packaging

The pen is polished one last time and packaged, ready to be enjoyed as a functional piece of art or gifted to someone special.

Each hand-turned wood pen is unique, reflecting the artisan’s skill and the natural character of the material. This process results in a one-of-a-kind writing instrument that is as beautiful as it is practical.