About this Product

BRILLIANT BEIGHT BEVELED TRANSOM

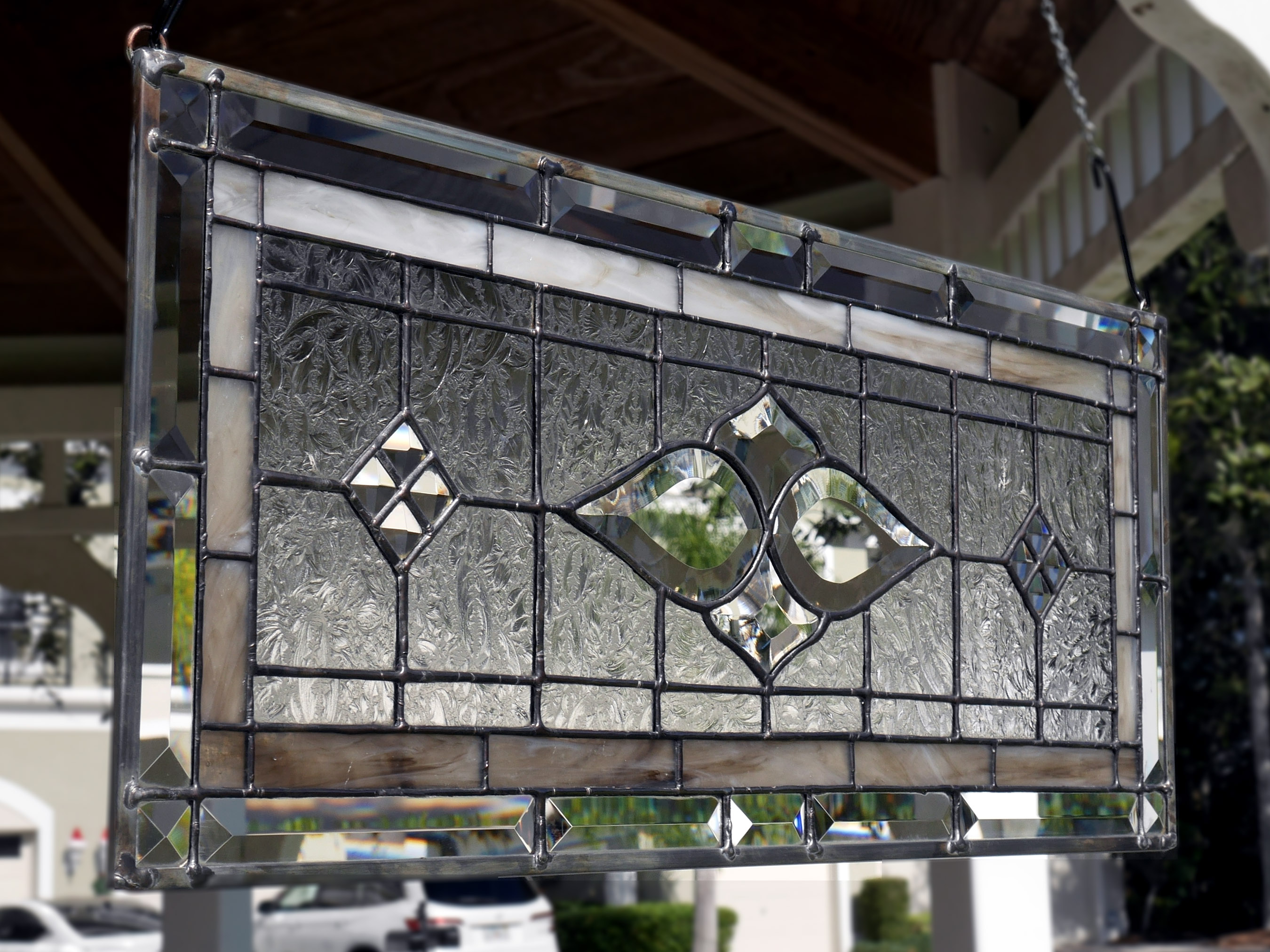

This traditional, yet contemporary design is an #SCWGlassworks hand crafted original. This stained glass transom features an 4 piece beveled glass cluster at the center framed by two clusters of square bevels. The centerpiece is surrounded by glue chip glass with light striations that glisten in the light.

The inner boarder is hand blown glass of streaky beige and cream that busts to life in the sunlight. The outer border is comprised of a chain of beveled glass rails, framing out the panel in regal elegance.

The sturdy zinc frame and all solder elements have been treated with a dark patina to give a well aged look, protected with Carnauba wax and buffed to a high polished shine. All pieces are studio quality, cathedral glass that will never fade in color. Sturdy rings are located on the corners panel for hanging.

Approximately 24.5 x 10.25 inch rectangle.

Shipped insured and double boxed and marked fragile.

Like where we are going? This design can be adapted to fit a custom size or be done in custom colors and textures to fit your exact needs. Just click the “Message Brian” button below and let’s create the perfect stained glass piece for you.

SCW Glassworks

Meet the Maker

Photographer, graphic artist, web developer and tech professional turned stained glass artist and following his dreams.

Some of my earliest memories are of Sunday mornings, looking at the patters and colors of the large windows in our church; observing the changes week to week the weather and the seasons had on them.

My step father pass the time during long Ohio winters painting with oils, a pastime that was just not me. Instead I found joy in photography. This began with capturing the right images with the right combination of lens, aptitude and speed. This then evolved to hours in darkrooms fine tuning exposure merinos to achieve mi vision. I called it “painting with light”.

Career life found me working with digital media often joking that PhotoShop was my second language. While it paid the bills, what I was created was limited by a computer monitor and not meant to last. I feel compelled to create something that would feel real, like old photo prints of my youth, something that would bring joy for years like this old church windows. This lead me to walk into my first stained glass shop….my world would never be the same.

This journey of eduction in the stained glass craft, has been an amazing one with tips from hundreds of artists in online communities and one on one guidance from local expert glass artists with decades of experience. The completion of each project lead to another. This excitement was only out shown by the joy of someone purchasing my work and hearing the stories of how that work brought joy others.

It is often said that you have to give something away in order to keep it. This is why I am proud to be part of goimagine.com and their commitment to helping children, giving the next generation the opportunity to follow their dreams too.

How it’s Made

Crafting stained glass art is a balance of art and mechanics that when done right result in a price that will last the test of time, bring years of joy. I take each project to heart knowing the intended owner has invested in stand glass for both it’s unique beauty and it’s ability to stand the test of time.

My process begins with the design itself, built both for beauty and for strength; each line is purpose built; to render the form and support the image it creates. Once the design is finalized, the right method of contraction is chosen. This panel uses the “Tiffany Method” pioneered by the Tiffany glass company at the beginning of the 20th century using copper adhered to each glass element that is then soldered together. This technique is great for smaller projects where thinner graceful lines holed everything in place.

I next select the glass, taking into account the opacity, colors & textures needed to fit the design I have imagined. Next I meticulous score and break and refine each glass element; shaping each piece to the exact shape needed. These elements are placed on the bench, checked and rechecked to assure accuracy.

After quality checking each element, they are all cleaned and then painstakingly wrapped in copper foil. As the coper is molded, bent and burnished, special care is taken to assure the thin layer of metal is the exact width from the edge of each piece of glass to maintain a uniform thickness to the final product’s seams.

The elements reassembled on the bench and tacked together using 60/40 solder (60% led & 40% tin). Once the elements are stabilized the solder is heated and applied to all seams. This slow process is an art all its own; a carful dance of heat and molten flows of melt binding together, all done carefully so as not to overheat the glass casing is to fracture and crack.

A frame of zinc is cut to fit the glass and welded together and rings added on for hanging. The sturdy zinc frame and all solder elements are treated with a dark patina to give a well aged look. The panel is protected with Carnauba wax that is applied and buffed many times over until to a high polished shine is attained.